A century-old partnership still ‘flours’ today

During the cold winter months, it’s the perfect time for baking fresh-out-of-the-oven cookies, pies and breads. That’s why flour is a key ingredient on grocery lists – and why flour milled by the North Dakota Mill and Elevator and transported by BNSF Railway has been keeping bakers stocked for 100 years.

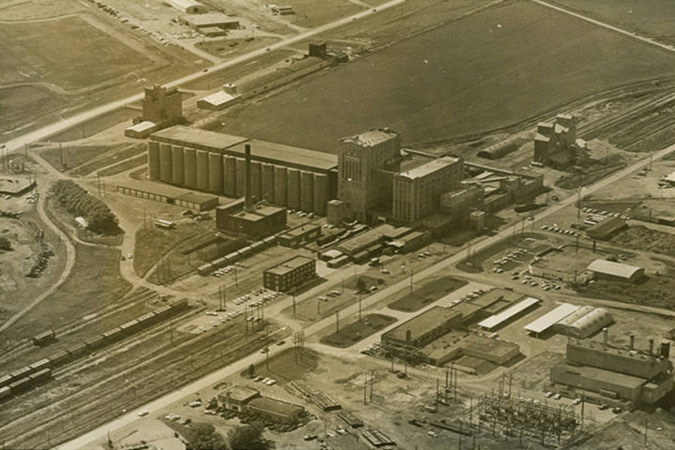

The Mill, located in Grand Forks, North Dakota, celebrated its century milestone last fall. Unique for being the only state-owned mill and the largest in the country, today the Mill continues growing its capacity.

“We respond to our customers and they have increased demand,” CEO and President of North Dakota Mill and Elevator Vance Taylor said. “So, we’ve focused on growth.”

In 2018, that meant the addition of an unloading “pit system” for dumping 40,000 bushels of wheat per hour from either rail cars or trucks, and a few years later, an additional 18,000 feet of railroad track to accommodate shuttle trains – a train with rail cars carrying the same commodity headed to the same destination.

Today, the Mill has more than 10 miles of track inside the facility, along with 10 milling units, a terminal elevator and a packing warehouse. As a result of its focus on growth, the Mill is roughly 10 times the size of its original capacity.

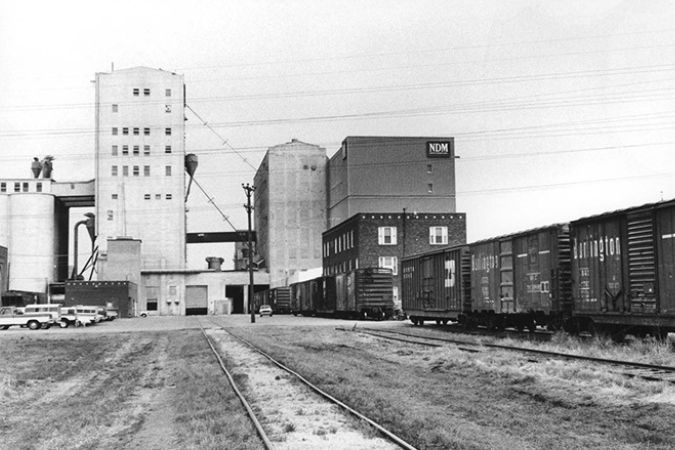

When a BNSF customer grows, we adjust to meet their transportation needs. So, train crews now working the “Mill Job” serve it six days a week directly from the Grand Forks yard. That means inbound rail shipments of primarily North Dakota spring wheat and durum arrive at the mill by shuttle trains for processing. Spring wheat is milled for flour and durum is made into semolina for pasta.

Eighty percent of the Mill’s product is shipped to its destination in bulk, either moving by train in Pressure Differential (PD) hopper cars or by truck. The rest is milled and packaged on site in smaller quantities according to specifications for various brands for retail sales, including Dakota Maid flour. As the Mill pursues additional markets, it expects to expand its branded product sales.

Working with the Mill and Elevator behind the scenes is BNSF’s Agriculture Ombudsman Matt Jensen. Before taking his current role, Jensen was a trainmaster working with train crews and employees in the yard to deliver the Mill’s rail cars.

“I was very familiar with their business because it’s such a big part of our daily work in Grand Forks,” Jensen said. “Now I’m helping them in a different way, by bringing more visibility to what we need to do to keep their rail cars moving.”

BNSF and our predecessors Northern Pacific (NP), Chicago, Burlington & Quincy (CB&Q) and Burlington Northern (BN) have been working closely with the Mill for all 100 years of its operations.

“I communicate with them daily,” said Kevin Johnson, Grand Forks yardmaster. “Because they’re just a mile from our yard, their proximity helps if we need to change the plan. They’re so close and accessible, we work with them and adjust. Our crews here in Grand Forks are first rate while working in some of the harshest conditions to get the job done.”

“The tracks the Mill added streamline our spotting process. We just cut off the cars on one track now. Before we would have to spot cars on several different tracks,” Johnson added. “It saves time for our crews and their employees.”

“We want consistent, reliable service,” Taylor said of his company’s expectations. “Our relationship with the local BNSF team couldn’t be better. We’re always in touch with them.”

Enough flour moves in one rail car to bake up to 2 million bagels, and 90 percent of the Mill’s customer base is outside North Dakota. That need for long-haul shipment makes rail the best option for the Mill to reach its customers.

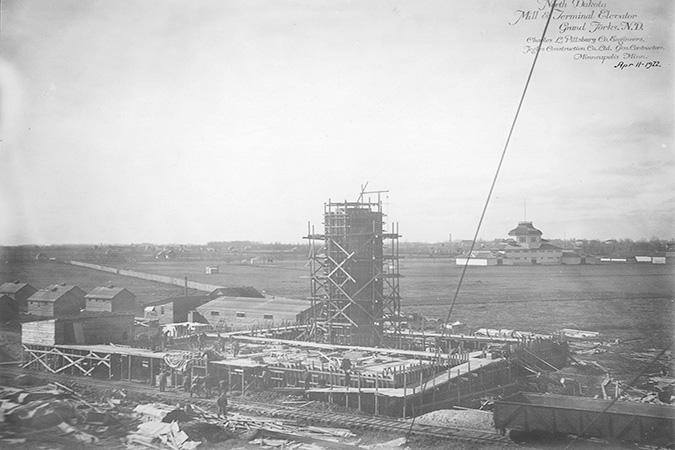

From the Mill’s beginning in October 1922, railroad access has been key to helping fill its mission to promote and provide support to North Dakota agriculture. Instead of settling for reduced profits from the Minneapolis-based flour mills and grain exchange, the state’s elected officials established the mill. No state funds support its milling operations and every year at least 50 percent of its profits go to the state’s general fund. The Mill brings the state value-added agricultural income, and its location, selected long ago on BNSF tracks, connects it to the rest of the country.